Construction Careers

TNT Development is in a period of rapid growth as we seek to reform the construction industry by pioneering the use of 3D concrete printing (3DCP) in our North Carolina region.

Roles We Are Hiring

3D Concrete Printing

· 3DCP Robotics Lead

· 3DCP Materials Operator

· 3DCP Materials Operator Helper

Construction

· Hands-On Helper

· General Trades / Forklift Operator

· Construction Site Laborer

Specialists

· Field Engineer / Site Clerk

· Safety Officer

Overseers

· Site Superintendent

· Project Manager

TNT utilizes building methods that have a low impact on the environment, maintain high quality, and create environments where families and communities will grow and thrive. We will continue to pioneer the use and development of new technologies in the construction industry to increase the efficiency of the building process. TNT will serve local communities by providing high-earning employment opportunities and generously sharing knowledge and company profits with our employees and the North Carolina triangle communities where they work and live.

Gain Experience With The Latest Construction Equipment

On August 8, 2024 TNT and Tvasta completed commissioning the FIRST-EVER Tvasta MOBILE ROBOTIC ARM SYSTEM deployed in the United States – the RD20. TNT Development has invested $650,000 to acquire its 3DCP RC20 device and its product catalog. We will continue to partner with Tvasta in the development of a 3DCP facility.

We Are Hiring To Train Workers In This Space!

What We’re Working On

TNT Development is heading the exciting project of building North Carolina’s first full neighborhood of 3D Concrete Printed houses. Odell Village is a groundbreaking development taking place in Littleton, North Carolina with backing from state and local governments designed to transform the real estate industry.

And we’re not just printing homes.

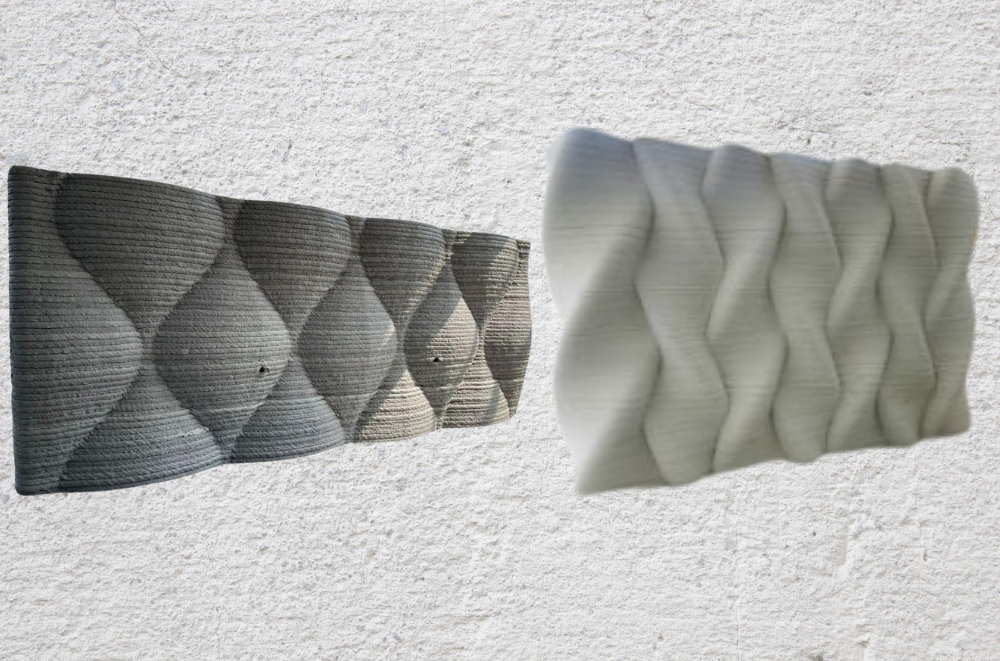

Our 3DCP technology will be used to print tables, seating, planters, facades, retaining walls and custom design projects.

Scroll Through Our Training Photos

Odell Village: 84 Home Project

Watch The Video To Learn More

About The Homes

Odell Village will feature 84 thoughtfully designed homes forming a cozy and innovative bungalow village that combines modern living with a sense of community. This neighborhood will consist of starter homes of two types; micro-unit tiny homes, and 2 bedroom starter homes. Each home is carefully planned to maximize functionality and comfort within a compact footprint, offering high-quality finishes, efficient layouts, and smart storage solutions.

Odell Village aims to tackle the affordable housing crisis, while brining more residents to the city of Littleton, North Carolina.

About Furniture & Decor

This market segment is growing rapidly because of rising interest in custom, durable, and sustainable designs. The range of 3DCP applications includes indoor and outdoor uses with innovations such as modular furniture, facade elements, and decorative pieces that are highly customizable and more eco-friendly than traditional manufacturing. Manufacturers use 3DCP to create intricate designs that are difficult or cost-prohibitive to achieve with standard concrete casting methods.

•Customization: 3DCP allowsfor highly customized designs, enabling unique and intricate furniture pieces that can be tailored to individual preferences and needs.

• Sustainability: This method can use recycled materials and produce less waste than traditional manufacturing processes, making it more environmentally friendly.

• Cost Efficiencies: 3DCP can be a more cost-effective way to produce furniture by reducing material waste and labor costs.

• Speed: The design to finished product process is much faster than traditional manufacturing.

• Complex Designs: 3DCP can easily create complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

About Retaining Walls

Retaining walls are essential structures designed to provide stability and support in areas where soil needs to be retained at different levels. They are commonly used in both residential and commercial projects to prevent erosion, manage water flow, and create usable spaces on sloped or uneven terrain. Whether for decorative garden borders or large-scale construction, retaining walls play a critical role in shaping and protecting the built environment.

•Durability: Can be made from solid, durable materials providing excellentstructural integrity.

•Efficiency: 3DCP’s precision reduces material waste and ensures that the walls are built to exact specifications, improving overall efficiency.

• Cost Savings: Like furniture, 3D-printed retaining walls can reduce labor and material costs.

• Speed of Construction: Faster than traditional methods, allowing for quicker completion.

• Design Flexibility: Allows for innovative and flexible designs ideal for variouslandscapes.

Apply To Work At TNT Development Today!

Email Our Team Your Resume With A Message Of What Position You Are Applying For!

Click To Email: admin@tntdevelopers.com

Work With An Innovative Construction Company

Contact Us

TNT Developement is a subsidiary of Cross N Crowns Ventures, Inc.

(c) TNT Developement 2021